Cangzhou Ever-Power Deceleration Machinery Co., Ltd. is a professional manufacturer in HebeiCycloid reducerManufacturers. XWD5-23-2.2kw cycloid reducer is a specific model of reducer.The manufacturer supports non-standard customization, and can produce various non-standard models of reducers according to customer needs.The cycloid reducer produced by the manufacturer can be widely used in food and grain machinery, printing and packaging machinery, environmental protection machinery, transportation equipment, chemical equipment, metallurgical mining equipment, iron and steel power equipment, etc.

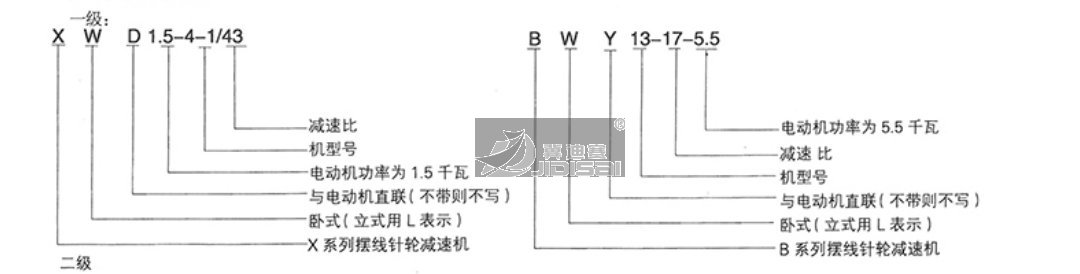

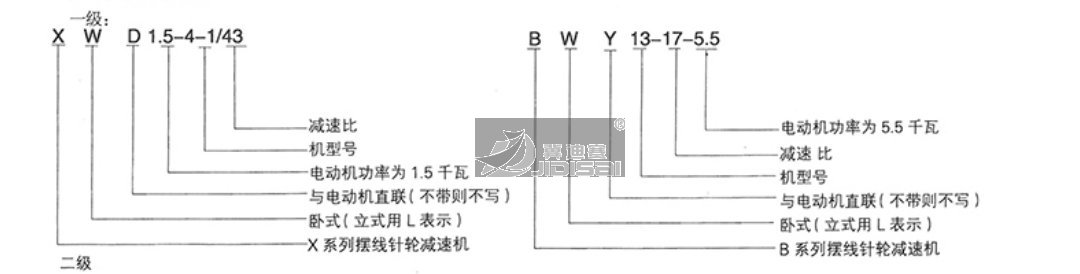

【Model Description】

X:X series planetary cycloid reducer

W: Horizontal

D: With motor

5: Frame number, indicating the size of the reducer

23: Transmission ratio (transmission ratio=input revolutions/output revolutions)

2.2kw: motor power

Model representation method of first-level cycloid reducer

Features of XWD5-23-2.2kw cycloid reducer

1. Large reduction ratio and high efficiency: the one-stage transmission reduction ratio is 9~87, the two-stage transmission reduction ratio is 121~5133, the multi-stage combination can reach tens of thousands, and the pin-tooth meshing system sets rolling friction, and the meshing surface has no Relative sliding, so the first-level deceleration rate reaches 94%.

2. Smooth operation and low noise: There are many pairs of teeth contacting at the same time during operation, the degree of coincidence is large, the operation is stable, the overload capacity is strong, the vibration and noise are low, and the noise of models of various specifications is low.

3. Reliable use and long life: Because the main parts are made of high-carbon alloy steel quenching treatment (HRC58-62), and then finely ground, and the cycloidal teeth mesh with the needle gear sleeve and transfer to the needle teeth to form rolling friction, friction The coefficient is small, so that there is no relative sliding in the meshing area, and the wear is very small.

4. Compact structure, small size: with the same powerReducerIn comparison, the weight and volume are more than 1/3 smaller. Because of the planetary transmission, the input shaft and output shaft are on the same axis to obtain the smallest possible size. 5. Exquisite workmanship, using high-quality raw materials.

5. Exquisite workmanship, using high-quality raw materials.

6. It can be equipped with explosion-proof motor, brake motor, 220V according to customer requirementsSingle-phase motors, frequency conversion motors, etc.

XWD5-23-2.2kw cycloid reducerDetails that should be paid attention to during installation

1.Cycloid reducerThe output shaft in the output device can withstand the axial impact force is limited.Should be used during installationThe shaft end is screwed for installation, and the coupling is screwed in..avoidDirect hammer reducer.

2. When installing, it is necessary to ensure the high fit of the corresponding size of the reducer, including the standard and horizontal height of the installation centerline, to ensure that the concentricity of the reducer is within the strict standard range.

3. In the rotation of the lubrication system of the equipment itself, the actual working environment of the reducer should also be fully considered, and the oil pump has production requirements to meet the lubrication of various parts of the reducer.4. To ensure that the appearance of the reducer body does not deform during the installation process, provide a horizontal working position, and arrange the bolts of the spacer block symmetrically.

5.In order to prevent the oil leakage of the reducer during operation, the inclination angle of the reducer is required to be controlled during installation.Within 15 degrees.