XWED cycloid reducer

XSeries horizontal direct-connected two-stageCycloid reducer

Technical specifications

【series】XSeries cycloid reducer

【Structure form】Horizontal

[Input terminal connection form] Directly connected to the motor

【Level】Level XNUMX

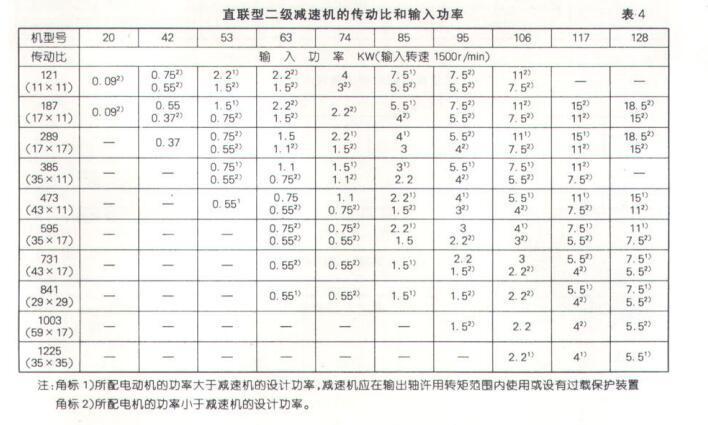

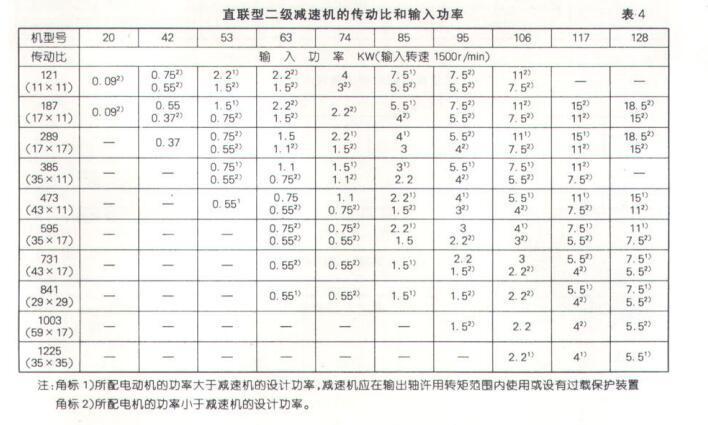

【Deceleration ratio】Level XNUMXXThe series reducer ratios are:131,187,289,391,473,493,595,714,841,1003,1225,1505,1849,2065,2537,3481,5133;(Please contact the website customer for specific reduction ratio selection)

[Machine model] Level XNUMXXSeries have14Species: 00,20,32,42,53,63,64,74,84,85,95,106,117,128(Please contact the website customer service for the specific machine model)

【Motor Power】As shown in the figure below

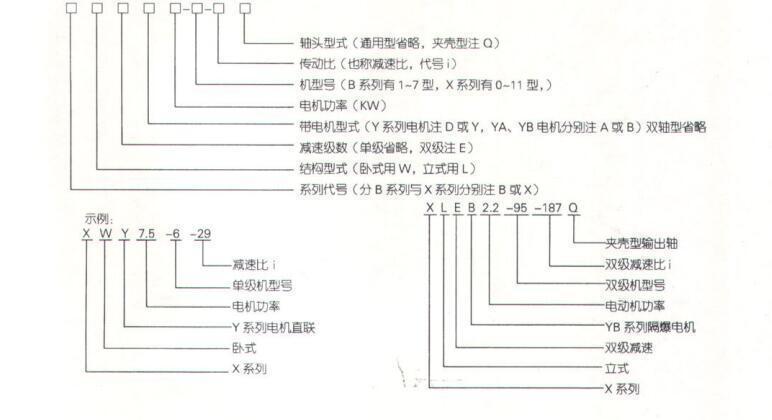

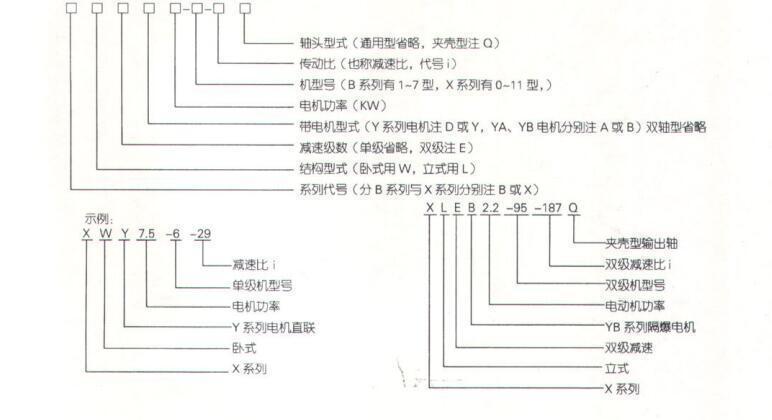

XSeries Cycloid Pinwheel Reducer Model and Representation Method

Product introduction

XWED cycloid reducer is based onReducerThe installation form is named.

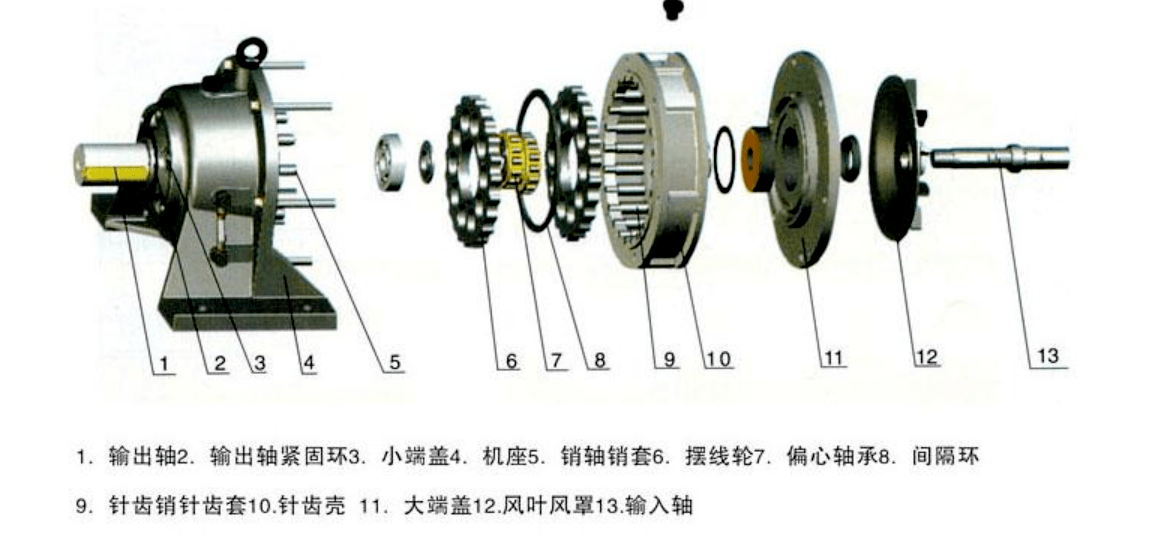

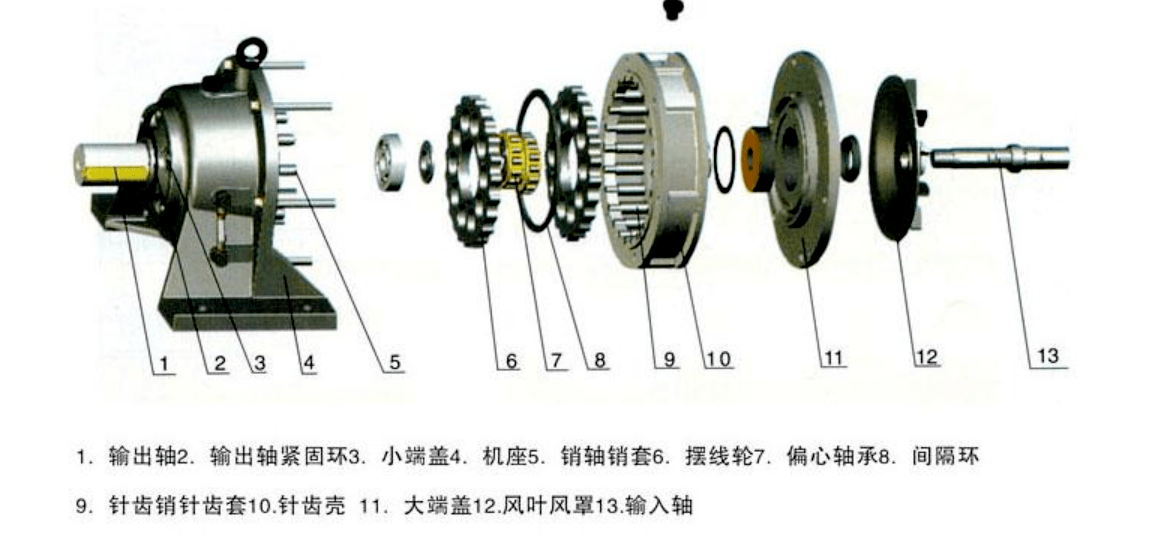

The whole transmission structure can be divided into three parts: input part, deceleration part and output part. Its input structure is a high-speed part, which is connected to the input motor (motor); its output part is the low-speed part of the reducer, and its output shaft passes through the sprocket or Couplings, connecting plates, etc. are connected to the equipment that users need to drive.

Features

1. The rotation ratio is large.X series cycloid reducerDivided into primary, secondary and tertiary rotation ratios.This series of reducers has a two-stage rotation ratio of 121-1225.The greater the number of stages, the greater the rotation ratio.

2. Compact structure and small size: Compared with other reducers of the same power, the weight and volume are more than 1/3 smaller. Because of the planetary rotation, the input shaft and output shaft are on the same axis, and a smaller size can be obtained.

3. Strong overload capacity, impact resistance, small moment of inertia, suitable for frequent starting and forward and reverse rotation.

4. Reasonable design, convenient maintenance, easy to disassemble and install, few parts, simple and convenient lubrication.

5. Reliable use, fewer failures, and long life.The parts are made of high-carbon alloy steel quenched and finely ground.In addition, the meshing of the cycloidal teeth and the needle gear sleeve is transmitted to the needle teeth to form rolling friction, and the friction coefficient is small, so that there is no relative sliding in the meshing area, and the wear is very small, and it is durable.

6. Smooth operation and low noise.The cycloidal pin wheel has a large number of meshing teeth, a large overlap coefficient and a stable mechanism, which minimizes noise and vibration.

Use range

1.Cycloid reducerIt is allowed to run in both directions, and it can work continuously for 24 hours a day.

2. Its unique stable structure can replace the cylinder in many casesGear reducer和Worm gear reducer.

2. Products are widely used in deceleration mechanisms in various transmission machinery, such as light industry, chemical industry, iron and steel metallurgy, automobile manufacturing, textile printing and dyeing, packaging and printing, machinery and equipment industries.

Appearance