| Name | Motion diagram | Recommended transmission ratio range | Features and applications |

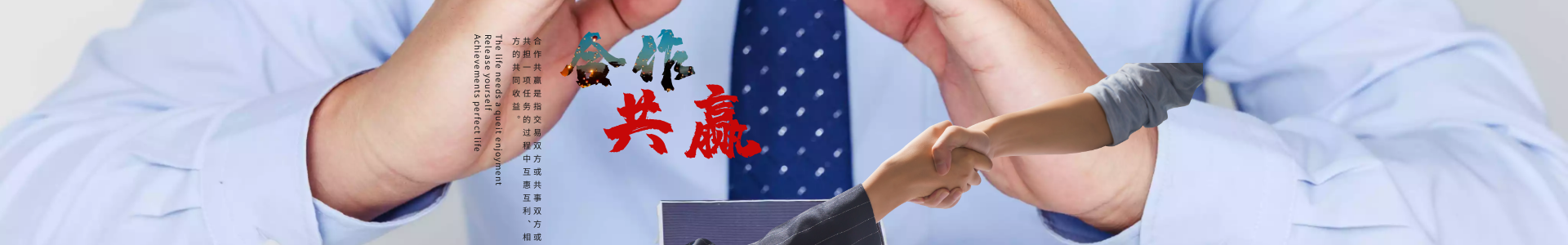

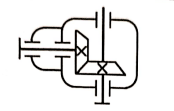

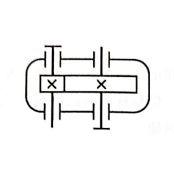

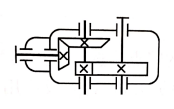

Single round Pillargear reducer |

| i <8 | The gear teeth can be made into straight teeth, helical teeth or herringbone teeth.Straight teeth are used for transmissions with low speed (v<8m/s) or light loads; helical teeth or herringbone teeth are used for transmissions with higher speeds or heavier loads.The box is usually made of cast iron, and sometimes welded structure or steel castings are also used.Bearings usually use rolling bearings, and sliding bearings are only used for heavy-duty or ultra-high speeds.Other forms of reducers are also the same as this type |

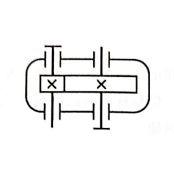

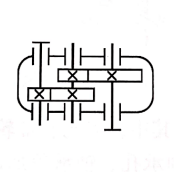

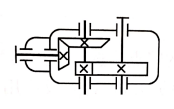

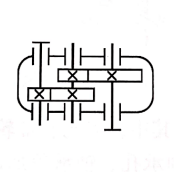

Two-stage cylindrical gear reducer

| Expanding |

| i=8~60 | The structure of the two-stage expandable cylindrical gear reducer is simple, but the position of the gear relative to the bearing is asymmetric, so the shaft should be designed with greater rigidity.The high-speed gear is arranged at the input end far away from the torque, so that the torsional deformation of the shaft under the action of the torque will reduce the uneven distribution of the load along the tooth width caused by the bending deformation of the shaft under the action of the bending moment. It is recommended to be used where the load is relatively stable.The high-speed grade can be made into helical gear, and the low-speed grade can be made into straight or helical gear. |

| Coaxial |

| i=8~60 | The length of the reducer is short, and the depth of the two pairs of gears immersed in the oil is roughly the same, but the axial size and weight of the reducer are relatively large; the load-carrying capacity of the high-speed gear is difficult to fully utilize; the intermediate shaft is long, the rigidity is poor, and the load Uneven distribution along the tooth width; there can only be one input and output shaft end, which limits the flexibility of the transmission arrangement |

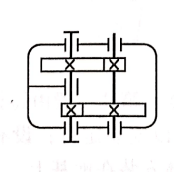

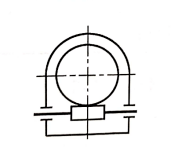

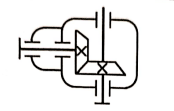

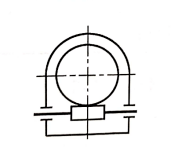

Single-stage cone

Gear reduction Speed device |

| i <6

| It is used for transmission where the two axes of the input shaft and the output shaft intersect perpendicularly, and can be made into horizontal or vertical.Due to the complexity of bevel gear manufacturing, it is only used when the transmission arrangement requires it

|

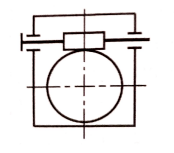

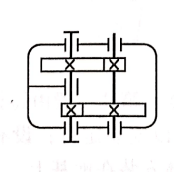

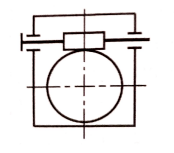

Cone-circle Column gear reducer |

| i=8 ~40

| The characteristics are the same as the single-stage bevel gear reducer.Bevel gears should be arranged at a high-speed level so that the size of the bevel gears is not too large, otherwise it will be difficult to process.Bevel gears can be made of straight, helical or curved teeth, and cylindrical gears can be made of straight or helical teeth

|

蜗

杆 Less Speed Device | 蜗 杆 On under Set formula |

| i=10~80

| The worm is arranged under the worm wheel, and the cooling and lubrication of the meshing part are better, and the lubrication of the worm bearing is also convenient.But when the peripheral speed of the worm is too large, the agitation loss of the oil will be large, and it is generally used when the peripheral speed of the worm is v<10m/s.

|

蜗 杆 On 上 Set formula |

| i=10~80 | The worm is arranged on the top of the worm wheel, which is convenient for assembly and disassembly. The peripheral speed of the worm is allowed to be higher, but the lubrication of the worm bearing is not convenient, and special structural measures are required.

|